Automotive Powertrain & Emissions Control Lab

About the Lab

Location: East Stadium

Coordinator: Pingen Chen

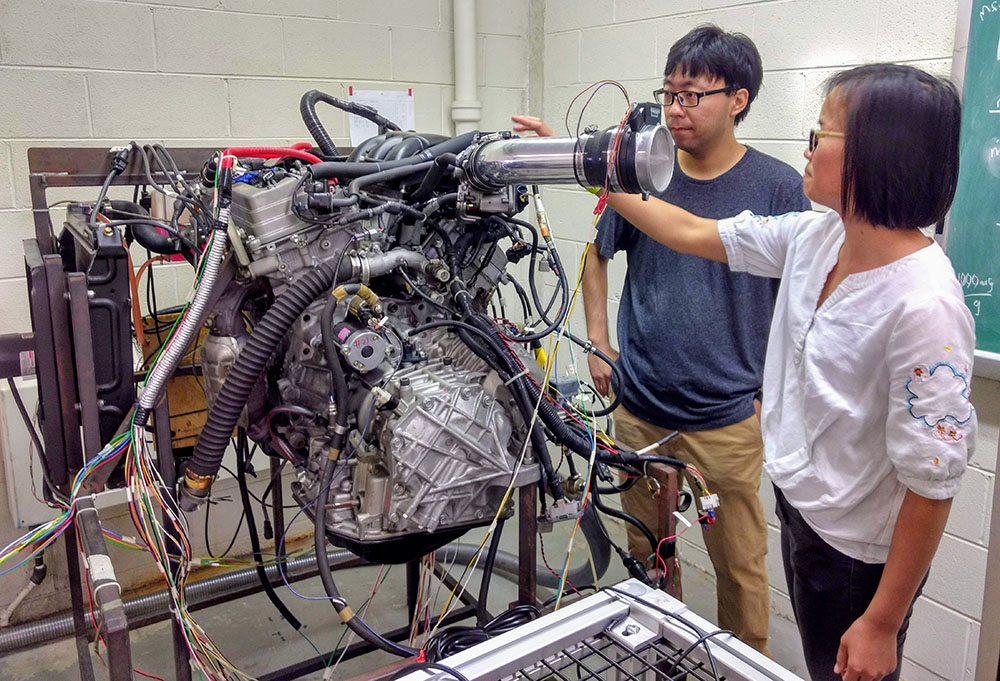

The Automotive Powertrain and Emissions Control Laboratory was established by Dr. Pingen Chen in 2016. The main research focuses on modeling, diagnostics, controls, and optimizations of various automotive systems including conventional/hybrid/electric powertrains, internal combustion engines, emissions control systems, sensors, autonomous vehicles, and advanced engine combustion with alternative/renewable fuels.

Lab Features & Highlights

This lab is equipped with the following:

Engines and Aftertreatment Systems

- 2GR-FE Toyota 3.5L direct-injection gasoline engine (x2);

- 2.5L Flat 4-cylinder Subaru Boxer gasoline engine;

- Cummins ISB6.7 Diesel Engine;

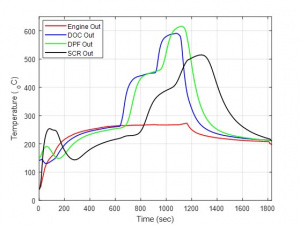

- Aftertreatment systems including Diesel oxidation catalyst (DOC), Diesel particulate filter (DPF), and urea-based selective catalytic reduction (SCR) system, NOx adsorber catalyst, Three-way catalyst.

- Nissan V6 3.5L direct injection gasoline engine and three-way catalyst (TWC)

- Mercedes Benz M274 gasoline engines (x4)

- Sensors: CAN-based NOx sensors, CAN-based ammonia sensors, CAN-based Bosch LSU 4.9 Lambda Sensor, differential pressure sensor, and thermocouples;

- Nissan Leaf electric vehicles with level-2 autonomy (adaptive cruise control and lane keeping), 226-mile EV range

Test Equipment

- DYNOmite engine dynamometer;

- DYNOmite EMS 5002 five gas analyzer;

- Engine starter engagement endurance tester.

- SuperFlow Black Widow high-performance water-brake engine dynamometer (Suitable for both gasoline engines and heavy-duty Diesel engine operations)

- MKS MultiGas 2030-1065, 5-Hz high-speed FTIR gas analyzer.

- MultiGas 2030-1065 FTIR Gas Analyzer

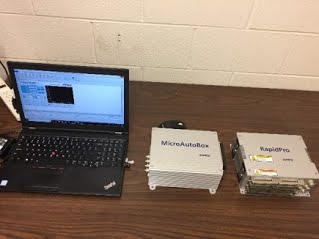

Rapid Prototype Control Equipment

- dSPACE MicroAutoBox

- dSPACE RapidPro Engine Control Modules

In-House Catalyst Hydrothermal Aging System

- Accelerated hydrothermal aging of Diesel aftertreatment systems on engine test bench

- Achieve high aftertreatment temperatures (>600 ºC)

Tennessee Tech Family Connection

Learn More About Our Programs